Surface Preparation

Needle Gun

Slide /

Needle Guns

Needle guns have been used in the coatings industry for many years.

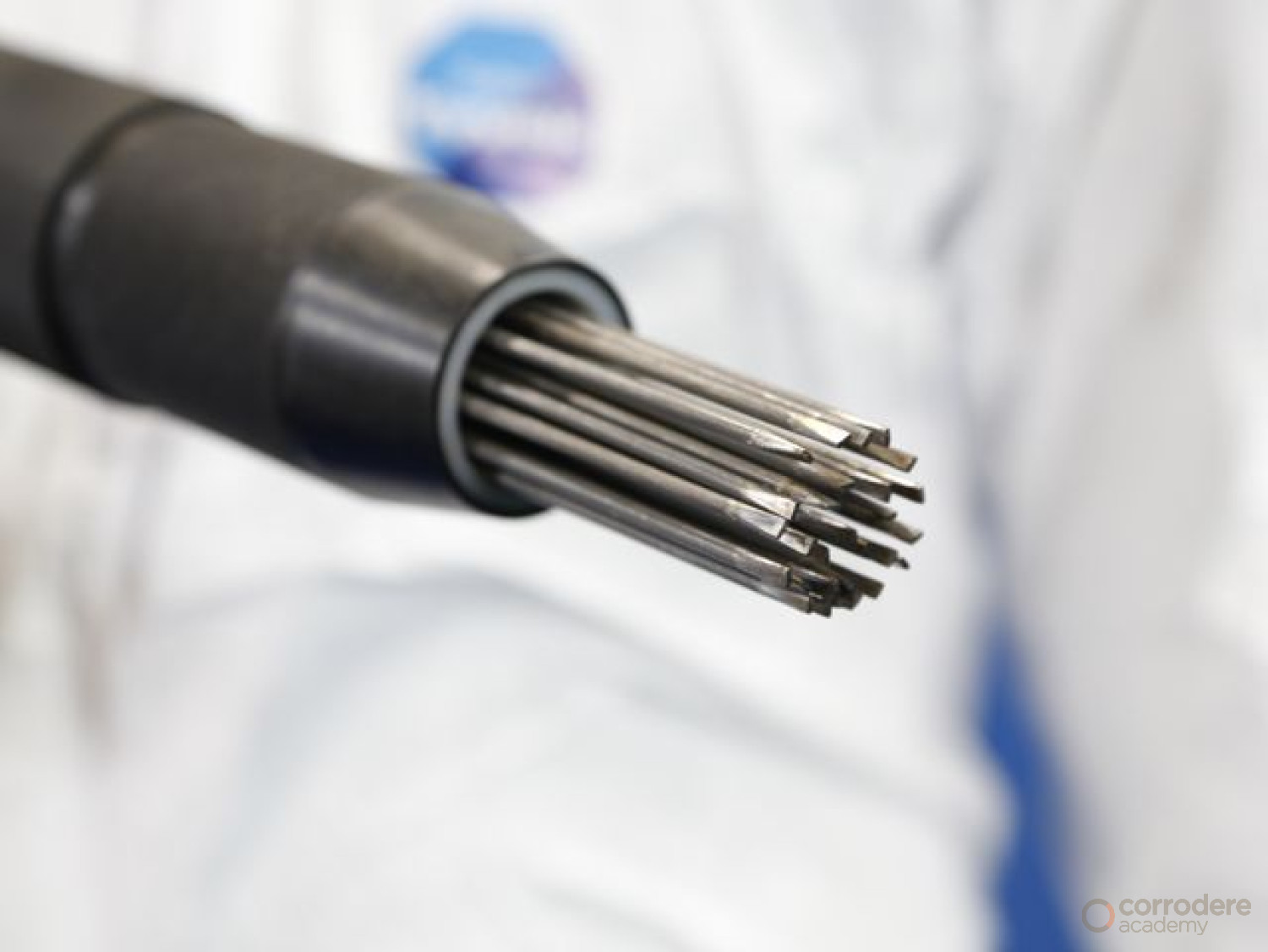

- Needle guns are available in many sizes, most hand-operated, as illustrated

- The tools are usually air operated with a simple connection to a compressed air line; however, electric versions are also available

- The tool is used for both pre-surface preparations and surface preparation

Needle Gunning

Needle guns -

- Handheld Tool

- Usually air powered; however, electric types are available and used

- The body of the equipment holds bundles of steel needles

- The piston pushes forward, hitting the needles against the substrate

- Various types of needles are available to suit the requirements of the task

Note: The needle sizes are typically 1-3mm (0.04 to 0.11 inch) and hit the substrate 2-3,000 times per minute.

Needle Gun in Operation

This is a simple animation of a needle gun in use

- The needles penetrate the surface shattering the coating or rust on the substrate

- A high surface profile is achieved and generally requires a high build coating (to cover the surface profile peaks)

Needle Gunning in Operation

Needle gunning in operation:

- Effective for removal of paint, thick rust and scale

- Limited use due to the vibration movement, which will cause problems to the operator over time

- Check risk assessments before you commence work

- The process generates lots of noise as the needles rattle the steel substrate

Needle Gunning Steelwork

Needle gunning is used on old steelwork to remove scale and rust, especially on weld locations, before high-pressure water jetting or abrasive blast cleaning.

- The process is quite labour intensive

- There is always a danger of penetrating the steel, so a test area on the steel should be conducted

- A high level of PPE and RPE is required for needle gunning

Manufacturer's Literature

Check the manufacturer's literature for the type and frequency of maintenance.

- The tools are relatively simple in design and the parts

- Replacement kits are available and should be stored on site

- Check for wear to the needles before use, and always look for general wear, tear and damage to the needle gun itself

Protection of the Operator

It is essential that the correct level of PPE and RPE is used when using needle guns.

PPE and RPE should include the following:

- Eye protection

- Ear defenders

- Gloves (hand protection)

- Goggles

- Correct body clothing

A strict working program must be conducted to ensure that the operator does not work more than the maximum allowed time, has the appropriate breaks etc. In addition, allow for sufficient break times away from the process.

Risk assessments have to be conducted on the works.

Health and Safety

Needle gunning can be very noisy as the needle penetrates the coatings and rust and hits the steel surface.

- The operator must have suitable ear protection for the task

- Eye and respiratory protection are also required as the paint and rust particles will be shattered, potentially hitting the operative

Full Face Protection

Where it is practical, it may be safer to use a full-face mask when using a needle gun.

- The full face mask could be fixed filters or air-fed; however, it is not always practical to wear such equipment

- If safety glasses are used, care must be taken when taking the glasses on and off as dust, rust and paint chips etc., can get into the glasses and the eyes

Hand and Arm Vibration

Hand-arm vibration is vibration transmitted into your hands and arms when using hand held powered work equipment.

Too much exposure to hand arm vibration can cause hand-arm vibration syndrome (HAVS) and carpal tunnel syndrome.

What is hand-arm vibration syndrome?

- HAVS affects the nerves, blood vessels, muscles and joints of the hand, wrist and arm

- It can become severely disabling if ignored

- It includes vibration white finger, which can cause severe pain in the affected fingers

Hand and Arm Vibration

Carpal tunnel syndrome is a nerve disorder which may involve pain, tingling, numbness and weakness in parts of the hand and can be caused by, among other things, exposure to vibration.

What are the early signs and symptoms to look out for?

- Tingling and numbness in the fingers (which can cause sleep disturbance)

- Not being able to feel things with your fingers

- Loss of strength in your hands (you may be less able to pick up or hold heavy objects)

Needle Gunning-Monitoring

If needle gunning is used continuously, the gun should have a timer attached so the user and company can monitor the usage or trigger time.

- The company should log the needle gun and the individual user to ensure that the user is not overexposed to the vibration

Note: this video demonstrates a needle gun in operation with a monitor attached to the equipment.

Needle Gunning

There are advantages and disadvantages to using needle guns by the protective coatings operative.

Advantages -

- Available in air and electric types

- Relatively easy to operate

- Suitable for penetrating scale and rust

- Generally small

- Low-level skill required

- Minimal parts

Needle Gunning

There are advantages and disadvantages to using needle guns by the protective coatings operative.

Disadvantages -

- Classified as a vibration tool that can injure an operator when overused

- Very noisy

- The needles could penetrate the substrate

- High surface profile achieved

Note: when used on coatings, the edges will still require disking to achieve a feather edge.

low Vibration Needle Guns

Low-vibration tools are now available, which reduces the stress caused by continuous use; however, the operator's time still has to be monitored and managed.

- A management process must be strictly observed to ensure the operative is not overusing such equipment.

Summary

Within this training unit, we have reviewed the use of needle guns as a method of surface preparation in the protective coatings industry.

We discussed the advantages and disadvantages of the task.

We also discussed the health and safety implications relating to vibration created by the process and the management requirement on time use.

Finally, we discussed low-vibration tools used to reduce stress caused by continuous use.